Quality, Production & Design

Design & Engineering

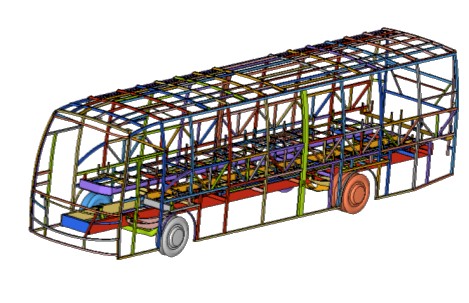

Design of bus body, it's

integration with chassis & systems

Design of bus body, it's

integration with chassis & systems

(e.g., AC, Heating, Electronics, Voice & Data Communication

Ventilation, Lighting, Trim & Seating etc.

As per customer needs.)

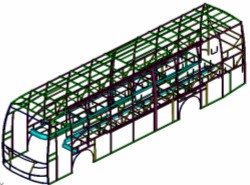

Weight optimization,

Standardization & Modular Design

Weight optimization,

Standardization & Modular Design

Alternative Materials

Alternative Materials

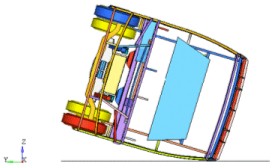

Design Validation & Testing

Design Validation & Testing

Design Targets on Quality, Cost &

Time

Design Targets on Quality, Cost &

Time

Design for Manufacturing &

Assembly.

Design for Manufacturing &

Assembly.

Supplier Base

Supplier Base

Minimum & Reliable Supplier base

on Q,C,D,D, MS Parameters (Quality, Cost, Design, Delivery &

Management Systems)

Minimum & Reliable Supplier base

on Q,C,D,D, MS Parameters (Quality, Cost, Design, Delivery &

Management Systems)

Homologation

Homologation

Arai & Conformance to Regulatory

Requirements

Arai & Conformance to Regulatory

Requirements

Manufacturing Technology &

Systems

Manufacturing Technology &

Systems

Compatible with Design, Customer

& Market Requirements

Compatible with Design, Customer

& Market Requirements

Shot Blasting

Shot Blasting

Design Facility

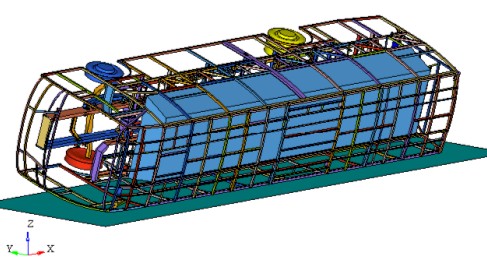

Azad group has it’s own in-house design facility where 2d & 3d drawings are made considering automobile norms for buses of all type, in India and exports.

we have various software to make these designs.

presently, Azad has more then 20 engineers looking after the design & development.

Azad Group Has Always Been Working Upfront To Design And Deliver The Products That Not Only Meets Customer’s Requirement But Should Be Safe For The End User.

To Prove This We Have Got Our Various Models Approved And Tested By Government Agencies.

These Models Are Rollover Worthy And Comply All Standards In India.

ROLL OVER FOR PASSENGER SAFETY

Key Customer's

Requirements

Bus features Required for global competitive success:

Value for money

Styling

Styling

Innovative and attractive styling

from inside to outside

Innovative and attractive styling

from inside to outside

Passenger & Driver Comfort

Ergonomics

Ergonomics

Low noise & Vibration, Seating,

Soothing Ambiance, AC/Heating, Ventilation, Lighting, Visibility

etc.

Low noise & Vibration, Seating,

Soothing Ambiance, AC/Heating, Ventilation, Lighting, Visibility

etc.

Safety

Driver, Passengers &

Pedestrians

Driver, Passengers &

Pedestrians

Product Quality

Reliable & Durable

Reliable & Durable

Cost

Lowest cost Manufacturer

Lowest cost Manufacturer

Time to market & Response time

(Flexibility & Agility)

Time to market & Response time

(Flexibility & Agility)

Operation, Profitable & Shorter

run time

Operation, Profitable & Shorter

run time